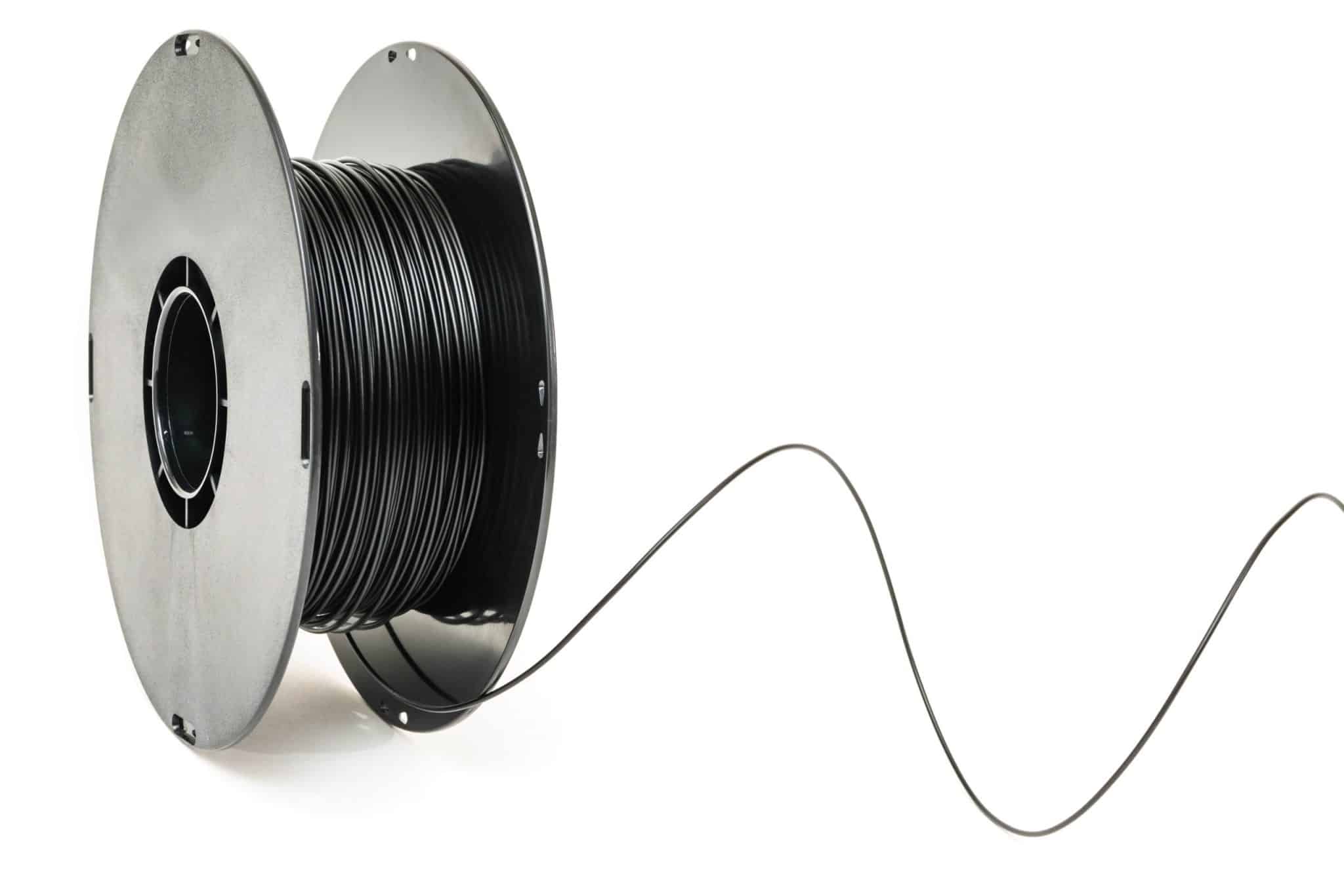

Flexible filaments are a popular material used in 3D printing. Before you choose which filament to work with, you must understand what your options are. What types of filaments are available? Which are the best brands?

What are Flexible Filaments?

Flexible filaments are plastic materials used to create objects with 3D printers. As you may have guessed, the material is flexible and made from TPEs or thermoplastic elastomers.

So, what exactly is TPE?

TPEs are polymers with properties that blend those of rubber plastic. In other words, it can be stretched and twisted easily while still retaining some rigidity. There are several types of TPEs, and each of their chemical structures varies – that means that some will be more elastic than others!

This allows different manufacturers to experiment with chemical formulas to create filaments as elastic as rubber bands, or as flexible as a tire.

Note that not all flexible filaments fall into the TPE category. However, these are the most widely used materials so this guide will focus on exploring them in greater detail.

Let’s review some important features of thermoplastic elastomers:

TPEs are soft and flexible and contain strong electrical properties. They can resist fatigue easily and dampen vibrations, making them ideal materials in the 3D printing space.

Even though TPEs are elastic and flexible, they still have a high impact strength. Objects made from TPEs can resist weathering, chemicals, abrasion, and more – so you don’t have to worry about your 3D prints degrading quickly.

Most TPEs can handle temperatures from -30 to 140 °C, which means it is suitable for almost any type of environment! Similarly, the material is recyclable so you can build 3D prints without worrying about damaging the environment.

TPEs are not a perfect material, though, and do have some drawbacks. For instance, their softness and flexibility can often make it difficult for 3D printer extruders to handle them well. Likewise, they can buckle when passing through the extrude.

They are also sensitive to rapid movement, which can cause uneven printing surfaces.

Also, the materials absorb moisture because they are hygroscopic. If you do not store your filaments properly, they can end up causing your 3D prints to sizzle and pop up when they are finished.

Flexible Filament Types

When it comes to flexible filaments that you can use in 3D printing, you have several options to choose from. As we mentioned, the chemical structures in each will be different and that will determine their flexibility and rigidness.

Here is a guide to the common types of TPEs:

Thermoplastic Polyurethane (TPU)

The most popular flexible filament is TPU or thermoplastic polyurethane. It is strong and highly durable, which means it is a lot more rigid than other options. The benefit of having a rigid filament is that it can pass through the extruder with ease!

There are many applications for TPU in 3D printing. If you have ever purchased a custom phone case, it is likely made from this material! You can also use it to create rubber mats, ski boots, or shoe insoles.

TPU has a unique application in the RC car space since it has the perfect features to create shock absorbers, tires, seals, and even O-rings. Part of the reason it is so effective here is that TPU allows the prototypes to resist the stress from sudden movements and impacts.

Pros

TPU is a highly elastic flexible filament, with ranges anywhere from 600% to 700%. Its shore hardness falls between 60A and 55D, and it produces excellent quality prints.

You don’t need to use a heated print bed when using TPU, and the material will not show much shrinkage or warping. There are not any noticeable fumes produced during the printing process, however, this material is not food safe.

The material is highly resistant to abrasion and can also provide substantial protection from greases and oils.

Cons

Print speeds are a bit slower with TPUs because it can be tough to push the right amount of flexible filament through the hot end. Using a direct drive extruder can significantly improve your 3D printing results, though.

Getting the right temperature is essential. If it is too hot, you will see strings on your print – if it is too cold, the layer adhesion will suffer.

Likewise, TPUs do not handle UV light very well.

Thermoplastic Polyamide (TPA)

Next on our list is TPA, which is a copolymer of flexible nylon and TPE.

So, what happens when you mix these two materials? You get a flexible filament that has the smooth texture of nylon combined with TPE’s flexibility!

This makes it the perfect material for producing goods like golf balls, medical products, and even ski equipment.

Pros

One of the benefits of working with TPA is that is highly flexible. It provides ideal layer adhesion and heat resistance, so you can produce details and high-quality prints.

The elasticity ranges from 370% to 497%, and it has a shore hardness from 75 to 63A. As you can see, it is less elastic and more rigid than TPU, but that makes it exceptionally durable!

Cons

Unfortunately, warping is common for prints made with TPA. You need to store the material in dry places, or else it will begin to absorb moisture.

Thermoplastic Co-Polyester (TPC)

Another type of flexible filament is TPC, which is made of an alternating sequence of short-chain and long-chain glycols. That means that it contains both soft and hard segments, making it an engineering-grade material.

In other words, while it is used for various industrial applications, it is not common for hobbyist 3D printers to use this material.

For example, companies will use TPC to make self-expandable polymer stents and bellows!

Pros

This material has a low density and a Shore hardness range of 40 to 72D. The elasticity can vary from 350% to 530%, and it has good thermal stability.

Its strength and resistance to high temperatures make it ideal for industrial applications!

Cons

TPC cannot be used for objects that need to be highly flexible, and they have less elongation at break.

Acrylonitrile Butadiene Styrene (ABS)

You can also choose to work with ABS, which is also part of the thermoplastic polymers group. Its name tells you exactly what it is made of: acrylonitrile, butadiene, and styrene.

ABS is a popular choice for building toys like legos, sports equipment, and low-cost prototypes for various industries.

Pros

This is a popular choice for at-home 3D printing since it is easy to use but still provides strong properties. For instance, it is lightweight, impact-resistant, and affordable!

ABS also has a low melting point, so you can use it with a smaller printer or for an injection molding process. It is also very safe to operate.

Cons

Even though ABS is great for use at home, it is not the best choice for industrial applications! The melting point is too low, and it does not offer enough strength and durability for those needs.

Polylactic Acid (Soft PLA)

The last flexible filament on our list is polylactic acid or PLA. This thermoplastic is made from renewable sources like sugarcane or cornstarch – not petroleum. PLA is also called soft PLA since it can be very rubbery.

It can absorb impacts and vibrations, so industrial applications include objects that need to bend and give without breaking or losing their shape. Likewise, PLA is food safe and can be used for utensils and food containers.

The blend of firmness and flexibility also makes this a great choice for pen grips and shoe inserts.

Pros

This material has a low carbon footprint and is often biodegradable. It combines strength, flexibility, and durability.

Having food-safe capabilities is another benefit since it allows you to create objects that can safely interact with food.

Cons

If you do not convert it to soft PLA, the material can be very brittle. Similarly, it can have various problems during the 3D printing process like difficulty going through the extruder.

Tony K

Senior Mechanical Engineer

"Fantastic platform for purchasing custom parts"

Jiga is the best way to get the parts you need, when you need them.

Popular Flexible Filament Brands

Now that you have a general overview of the flexible filament materials available, let’s review some popular brands you can choose from.

MatterHackers Pro

MatterHackers has a wide range of flexible filaments to choose from. Their color options are second to none, and they are well known for producing high-quality TPU flexible filament.

This specific material has a shore hardness of 90A, which makes it relatively bendier than other options. MatterHackers even offers a more flexible option with their Pro Series Flex TPE!

You can print from 15 to 30 mm/s with this filament, and the cost is about $45 per spool.

Cheetah TPU

Cheeta TPU is a filament produced by NinjaTek, a popular name in the industry. This material was built to allow you to print at quicker speeds – hence the name Cheetah – without sacrificing quality and durability.

It can operate at up to 60 mm/s, which is almost as fast as what you can obtain with ABS! You can print faster with this option because of its shore hardness of 95A.

The cost of this filament ranges from $55 to $85, and you can choose from several different diameters and sizes: 05. kg or 1 kg, and 1.75 mm or 3 mm. NinjaTek also offers a wide variety of colors, so you can create objects in whichever color you’d like!

Polymakr Polyflex Filament

Another great TPU option is Polyflex Filament by Polymakr.

The shore hardness rating for this material reaches up to 95A, so it is comparable to the NinjaTek filament we just described. However, they mention that the hardness can vary down to 90A, so humidity and temperature may play a role.

So, if you need specific hardness requirements, this may not be the best option. Their color choices are limited too, and you can only buy it in 750 g spools.

FormFutura FlexiFil TPC

This next flexible filament is unique because it is constructed from bio-oils. FlexiFil TPC is like Polyflex and has a range of hardness: 92 to 94A.

You can purchase this filament in 0.5 kg spools, and the print speeds must be slow for it to work properly. Failure to keep the printer moving between 10 to 20 mm/s can cause the filament to buckle within the intruder.

If you are not in a rush to finish your prints, though, this is an environmentally friendlier option.

It is also important to note that some users have commented that their colors do not match what was expected – so consider this if you need specific colors.

Taulman3D PCTPE

Taulman 3D PCTPE, or plasticized copolyimide TPE, is made from a chemical compound of TPE and Nylon. This material can print easily because it is less elastic and flexible but has the durability of nylon.

Even though they do not advertise a specific shore hardness level, it is estimated to be above 100A. With that said, this is not the best material for objects that need to flex or bend. If you need something as durable as nylon that is slightly more flexible, though, it will get the job done!

XYZ Flexible Filament

XYZ has developed a proprietary filament designed for both durability and flexibility. It is waterproof and non-toxic, so it has a wide range of applications.

It comes in a cartridge that is very easy to use, and even includes a chip that lets you know how much material remains in the spool.

XYZ flexible filament can complement PLA and ABS projects too since they provide shock absorption, durability, and elasticity.

Recreus Filaflex TPE

Finally, we have Filaflex TPE by Recreus. This flexible filament is a direct competitor to those offered by Ninjaflex.

Out of all the materials on this list, Filaflex is the softest. It has a hardness level of 82A, which is ideal for printing very flexible objects. It is necessary to note that you may need a special extruder and thermal insulator to get the most out of this material!

It boasts an impressive elongation to break of 700%, but you probably don’t need this level of stretch for most applications. This option comes in a wide range of colors, and you can choose from 250g and 500g spools.

Yoav A