Minimum lead time

Price range

Tolerances

Layer Height

Wall Thickness

Max. Part Size

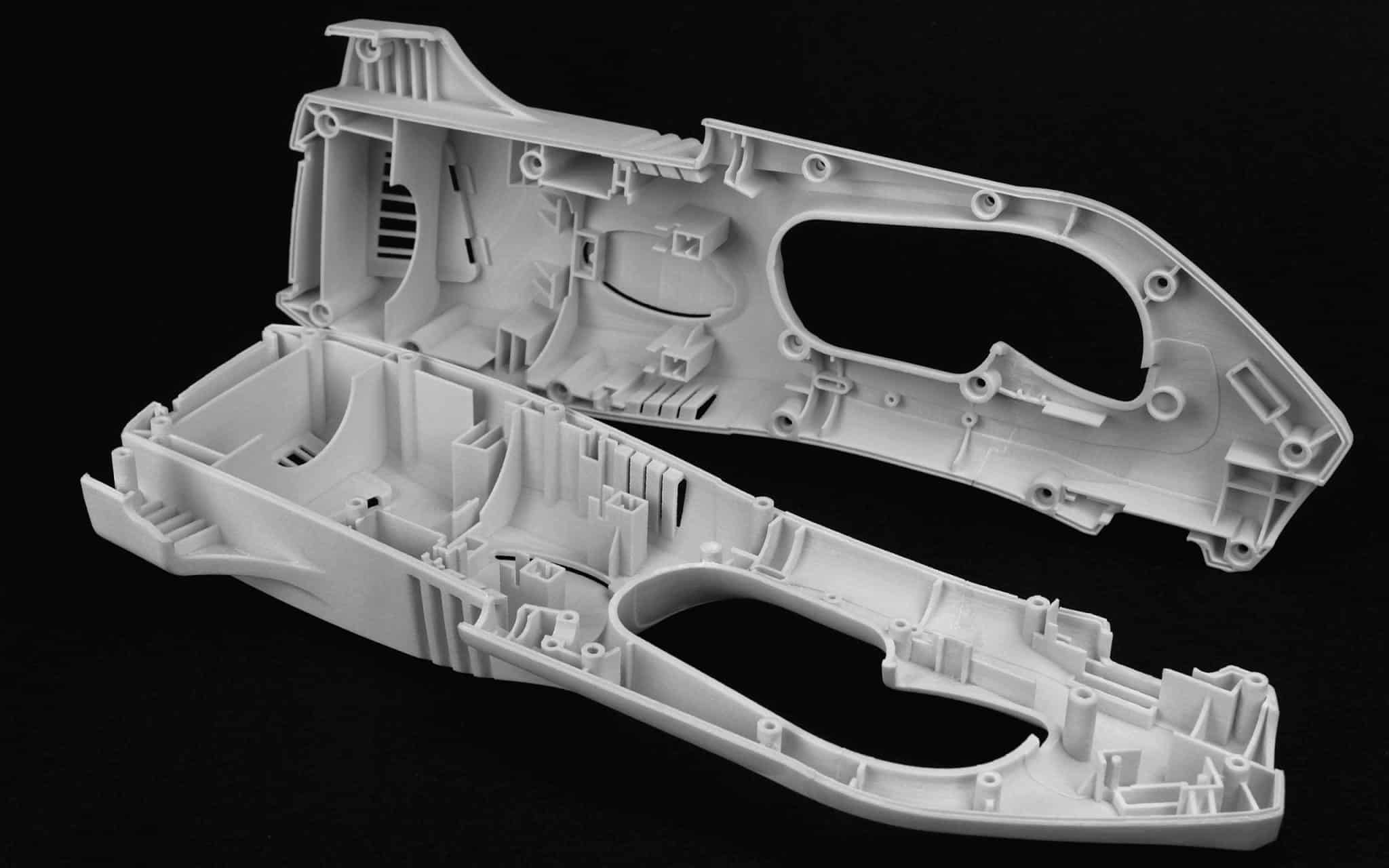

Nylon has three remarkable strengths. First, it has high impact resistance. It can stand impacts from situation like it was dropped or when parts are constantly banging together. Second is that it is resistant to abrasion. Nylon is an ideal material for when it is used in applications with moving parts because its low reaction to friction. And lastly, nylon is very flexible especially when produced in thinner geometries. It can be twisted and flexed repeatedly without fracturing or breaking the material.

Along with its advantages, using Nylon also has its disadvantages. It is not suitable to be used for heightened temperature applications. Once it breaks, it will have sharp edges. Lastly, it is colorless (white or black for SLS and black or gray for MJF).

Standard PA 12 is an ideal material in producing functional parts and prototypes because of its overall great mechanical properties, and of its resistance to chemicals.

Glass filled PA 12 has better resistance to abrasion and thermal compared to standard nylon because it contains glass particles which also adds high stiffness to parts.

The very first product that was made from nylon were toothbrush bristles. It was almost exactly one year after it was patented on February 16, 1937 by Wallace Carothers. Soon after its first appearance in the market, it started being used in food packaging, car engines. clothing, fishing line, and in 3D printing.

© 2024 Jiga, Inc. All Rights Reserved.