Minimum lead time

Price range

Tolerances

Layer Height

Wall Thickness

Max. Part Size

PLA can be considered as one of the best options in 3D printing because it has no fumes and easier to print.

PLA has a lower melting point compared to many fossil-based plastics and therefore melts easily and requires lesser energy to transform it into products. Also, PLA is made from renewable raw materials. Since it is produced from crops, PLA has reduced carbon footprint because crops absorb carbon dioxide when growing, and it takes less energy. This means that it produces less greenhouse gas to produce PLA compared to fossil-based plastics.

PLA has a lower melting point, thus, it cannot be recycled along with other plastics with higher melting point. Crops are used in the production of PLA; in this process, one should beware of bad agricultural practices such as overusing of fertilizers and GMO and the destruction of natural habitats. The residue in making PLA, though compostable, doesn't prove to improve the quality of soil because it has no nutrients. Instead, it makes the soil more acidic because of the change it makes to the soil's PH value.

Low melting point makes PLA unsuitable for high temperature applications. PLA may even show signs of getting soft or deforming on a hot summer day.

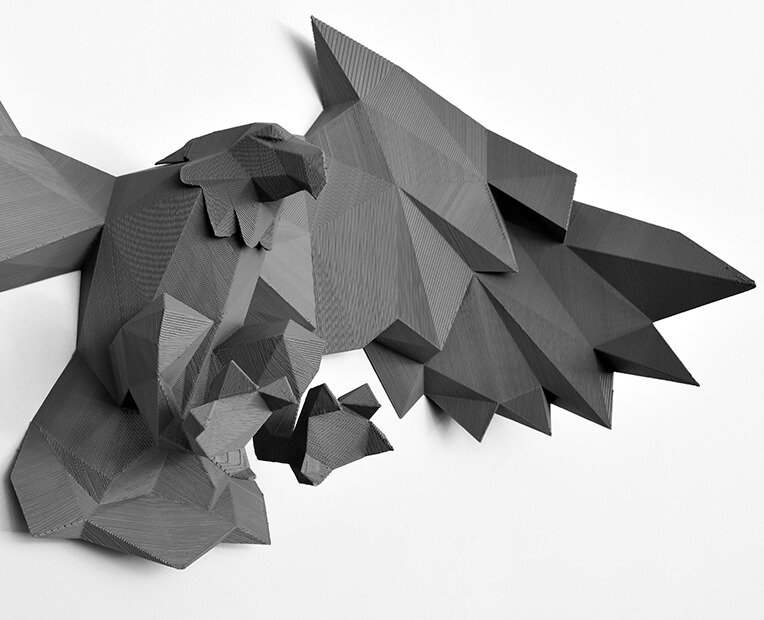

PLA (FDM) is used by most companies in producing non-functional prototypes with great details. Though more brittle than ABS, it offers greater detail than it.

Poly Lactic Acid or more commonly known as PLA, has 45% market share of the most commonly used plastics in 3D printing. PLA is one of the most environmentally friendly bioplastics in available in the market today because it is recyclable and biodegrable. Also, it only takes 1.6kg of sugar to produce 1kg of PLA-- that's how efficient it is.

© 2024 Jiga, Inc. All Rights Reserved.