Minimum lead time

Price range

Tolerances

Layer Height

Wall Thickness

Max. Part Size

Polycarbonate is highly durable and moderately flexible. Not only that it is impact and shatter resistant but it is also heat resistant up to 135 °C compared to PLA that can be deformed at only 60 °C. Also, it is transparent and ellectrically non-conductive.

Since Polycarbonate has high heat resistance, it requires higher temperatures to be extruded prorperly. It also absorbs moisture, and may also shrink and warp over time.

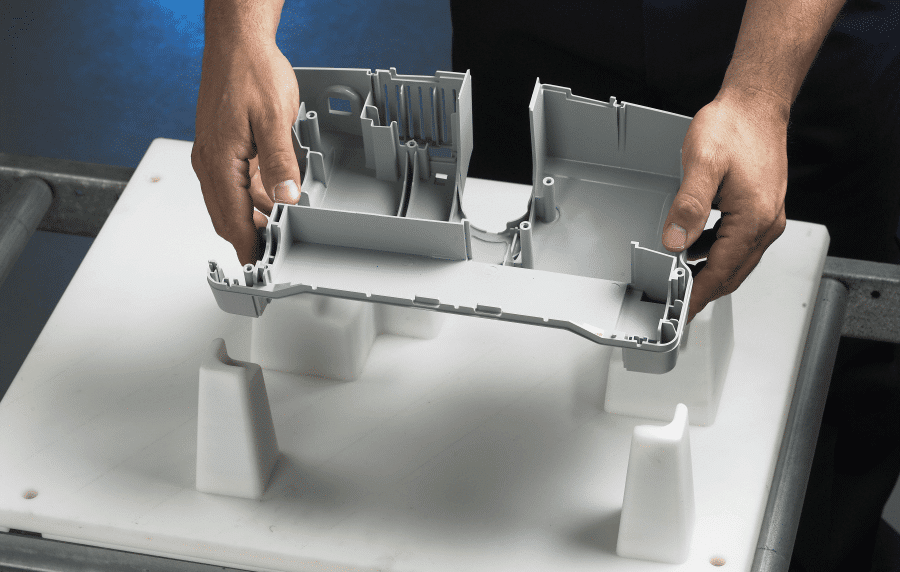

Polycarbonate has excellent resistance to strength and high temperature. It can be used in applications like connectors, power distribution (covers and housings), and battery boxes once it undergo CNC machining.

When polycarbonate was invented by the aerospace indsutry, its orginal purpose was to be used for astronaut visors.

© 2024 Jiga, Inc. All Rights Reserved.