Minimum lead time

Price range

Tolerances

Layer Height

Wall Thickness

Max. Part Size

If you choose FDM, you don't need to worry about scalability as it is one of the biggest advantages of this technology. The only reason that you will encounter problems in changing the size of the build area is the movement of each gantry. Material flexibility is another advantage that FDM is known for. Printing exotic filaments and a wide variety of thermoplastic materials even with few customization and upgrades will be an easy task if using any FDM printer.

One of the most talked about disadvantages of FDM 3D printing is part quality or detail. The material undergoes extrusion in layers causing it to have predefined thickness. Thus, printing high detail prints often requires numerous post-processing just to achieve high quality and professional-looking finish.

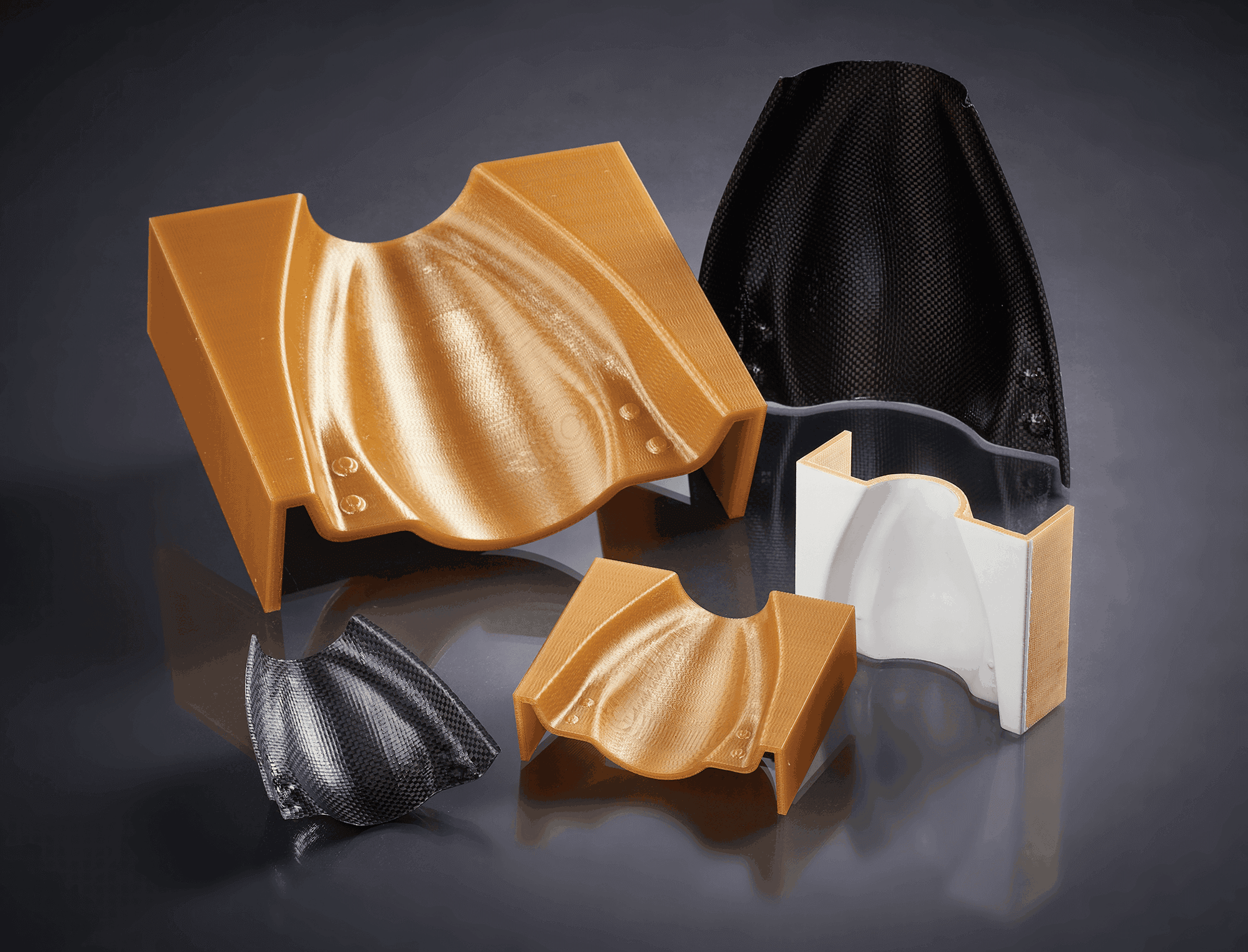

Polyjet printing is mostly preferred by automotive, electronics, and consumer goods companies. Companies that are engaged in clothing manufacturing and medical development also choose Polyjet over other printing technologies. This is all because printed prototypes look extremely realistic and closely resemble finished products.

FDM was conceptualized by scientist David E.H. Jones. It was introduced to the public in 1974, making it the oldest and therefore most popular 3D printing technology. True to this day, the largest number of 3D printers utilizes it.

© 2024 Jiga, Inc. All Rights Reserved.