Minimum lead time

Price range

Tolerances

Layer Height

Wall Thickness

Max. Part Size

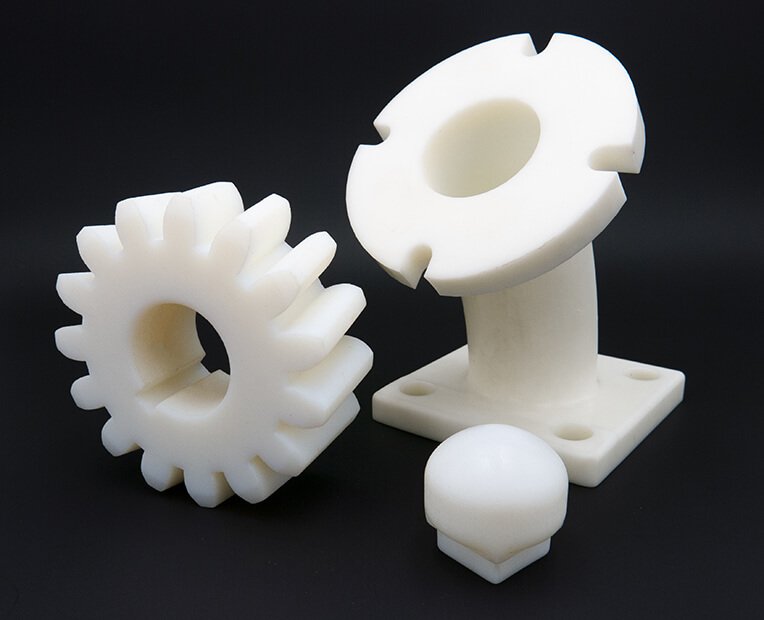

One good thing about VeroWhite is that it is water-resistant. It is also stiffer and stronger in respect of the industry's average tensile strength, flex strength, and flex modulus. In this regard, VeroWhite is superior to other standard engineering plastics such as ABS.

Though VeroWhite is water-resistant, it is not waterproof. Although it is stiff and strong, it is more similar to acrilyc than ABS, PC, polypropylene, or polyamide, and this is the reason why it is more suitable for light functional testing, patterns, models, and prototypes.

VeroWhite resin can 3D print objects precisely and with smooth surface. This makes VeroWhite a good material for ornamental objects. This can also be used in producing realistic prototypes and can be used to produce end-use products due to its accuracy, precision, and smooth surface finish. VeroWhite's final product has naturally smooth opaque surface.

When VeroWhite is dyed black, it results into a really dark black. And when printed and compared to the printed VeroBlack part, it conceals the build lines because it has a noticeably less glossy look. Also, after dyeing, there is a significant change to the texture of the product. The surface becomes slightly rough and has a cloth-like feel instead of its original plastic feel.

© 2024 Jiga, Inc. All Rights Reserved.